“We believe Fictiv is the category leader transforming how companies like Honeywell gain unmatched productivity, efficiency, and enterprise scalability through digitized workflows that dramatically change the speed and quality of manufacturing in markets such as energy, healthcare, space, and transportation."Īside from speed, Evans said Fictiv's quality is what keeps its customers returning. “Fictiv has differentiated itself as an innovative digital manufacturing solution that provides not only unprecedented speed but also scalable partnerships that deliver an immediate ROI and end-to-end business value,” said David Lincoln, managing partner, Activate Capital.

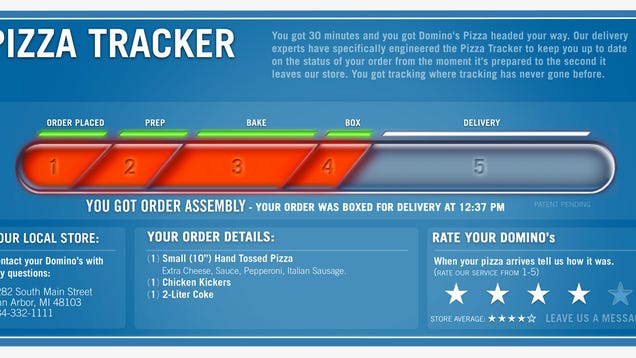

#Dominos order tracker series#

In 2021, Fictiv saw 100% year-over-year growth in core business revenue and an 81% growth in employees.įictiv’s manufacturing services are accessible on-demand through a cloud-based platform to solve customer challenges across new product development, engineer-to-order parts, and maintenance, repair, and operations.Īctivate Capital led Fictiv's series E round, which also includes new investors from Angeleno Group, Cross Creek, The Westly Group, and existing institutional investors including Accel, Bill Gates, G2 Venture Partners, and Standard Investments. "This type of speed delivers real business value to us and the productivity benefits have been profound," Williams said.įictiv has grown exponentially since its founding in 2013 as the demand for cloud-based, virtualized manufacturing continues to skyrocket. The company began working with Fictiv in September 2021. Outside of medical, the company also works with well-known firms like Honeywell, which turned to Fictiv specifically to help address challenges in its supply chain.Īs supply chain disruptions continue to impact manufacturers across all industries, San Francisco, CA-based Fictiv is helping to decrease supply chain risk for its customers. The $100 million series E round brings the total investment in the company to $192 million.įictiv says its customers have seen cycle time gains of 40% or better, engineering productivity of 20% or more, and a significant reduction in operational costs associated with managing an inflated, fragmented supply chain.Īnother Fictiv partner is RBC Bearings, which makes custom engineered precision bearings and products. Sean Williams, general manager at RBC Bearings, said Fictiv has streamlined RBC's workflows to reduce quoting time down from seven days to minutes or seconds, and its lead times down from weeks to days. That's what we're doing every single day."įictiv's other medical device customers include Medtronic, Johnson & Johnson, and Intuitive Surgical. "Customers that are building highly-engineered products that need, we're talking down to the human-hair width of tolerances. "That's our other bread and butter," Evans said.

Medical is about a third, if not more, of Fictiv's business, he said, and about 10% of the company's medical business is in the surgical robotics space. "If you think about this pace of innovation, we can talk about on-demand manufacturing, what we're doing, all the technology, how this $100 million will accelerate it, but it's how do you take a TransMed7, make sure that they can build devices, and their business goes from a six-year development schedule down to one year? And they're producing a very high number of tools," Evans said. "I think that's a really great example of how we're driving transformation in the medical space."

It's case studies like TransMed7 that set Fictiv apart from traditional contract manufacturers, and why investors just poured $100 million into Fictiv through its series E round. ".They built just over 40 injection-molding tools with us in seven months." We brought that down to a year," Fictiv CEO Dave Evans told MD+DI. "Before they met us they're typical development cycle was about six to seven years to make a medical device. So TransMed7 took a different approach and leveraged Fictiv’s cloud manufacturing network. TransMed7, which will soon hit the market with its SpeedBird and Concorde breast and Heron prostate biopsy instruments, is a perfect example of how digital manufacturing can transform a business.įrom inception, the startup's co-founders knew that the traditional development-to-market cost for the type of medical devices it wanted to make would be prohibitive.

0 kommentar(er)

0 kommentar(er)